Description

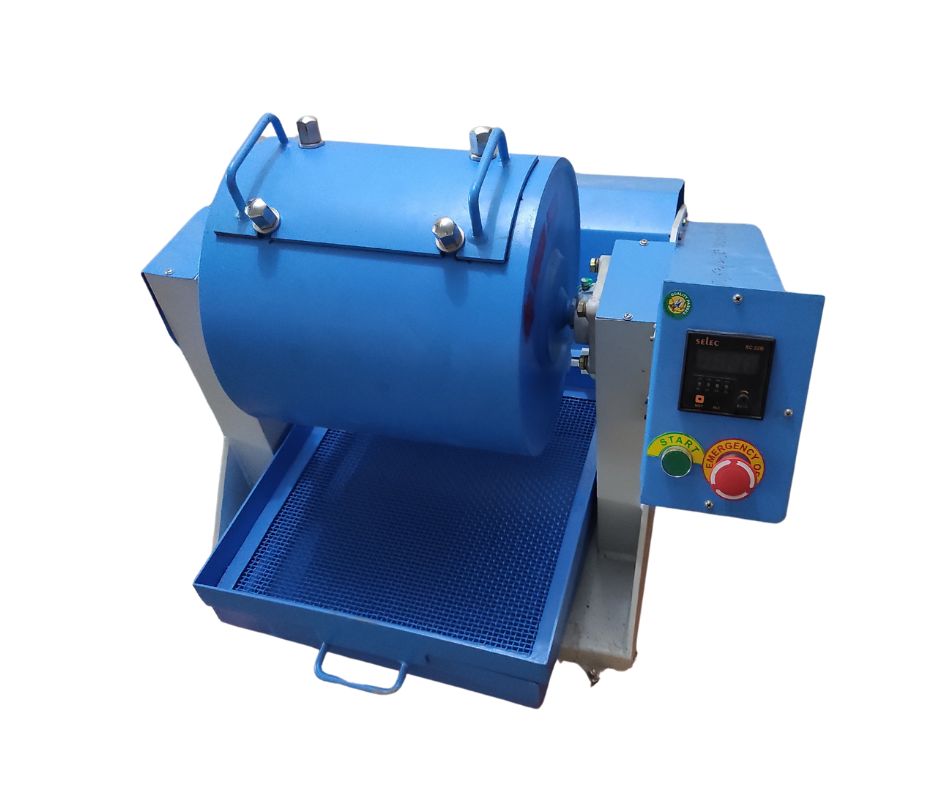

A ball mill consists of a rotating cylindrical shell, partially filled with grinding media such as steel balls, ceramic balls, or other spherical media. The cylinder is mounted on a horizontal axis and rotates around it, either continuously or in a batch-wise manner. As the cylinder rotates, the grinding media inside are lifted up on the rising side of the shell and then cascade or tumble down due to gravity. This motion results in repeated impact and attrition between the grinding media and the material being processed, thereby reducing the particle size.

Ball mills may be classified into:

Horizontal ball mills

Vertical ball mills

Planetary ball mills (which use a rotating base and spinning jars for finer and faster grinding)

Vibratory ball mills (which use high-frequency vibration)

The efficiency of grinding in a ball mill depends on several key factors:

Speed of rotation: Typically expressed as a percentage of the critical speed, which is the speed at which the grinding media would be held against the wall due to centrifugal force.

Size and density of the balls: Smaller balls provide more surface area for finer grinding.

Filling degree: The volume of the grinding media and material in the mill.

Material of construction: Both the grinding media and the cylinder can be made from various materials, depending on the application.

Ball mills can operate in:

Open circuit, where material passes through the mill once

Closed circuit, where oversized material is continuously recirculated

Ball mills can be used for:

Dry grinding, where the material is ground without any liquid

Wet grinding, where water or another liquid is used to assist in the grinding process

—

Applications:

Mining and metallurgy: Grinding ores to liberate valuable minerals

Pharmaceuticals: Preparation of fine powders for tablets and capsules

Ceramics: Mixing and grinding clay and glazes

Chemical industry: Homogenization of chemical powders and pigments

Construction: Preparation of cement and other construction materials

Nanotechnology: Production of nanoparticles through high-energy ball milling

—

Advantages:

Simple design and robust construction

Capable of grinding a wide range of materials

Can produce very fine powders (down to nanometer scale)

Suitable for both small-scale laboratory use and large-scale industrial applications

—

Limitations:

Relatively high energy consumption

Long milling times may be required for very fine particles

Wear of grinding media and mill liners may contaminate the final product

Overall, the ball mill is a key piece of equipment in the field of material processing, offering high performance and flexibility for a wide array of industrial and scientific purposes.

Reviews

There are no reviews yet.